Solving problems, embracing challenges

AMS Micromedical is a leader in the micromedical industry with a creative staff that can solve even the most complex problems and challenges. Our capabilities include engineering, precision micro-machining, plastic injection molding, parts finishing, laser engraving, packaging, and more. Request a quote or contact one of our helpful experts to get started on manufacturing your micro-medical devices today.

Custom, ultra-precise, USA-made micro medical solutions

The AMS Micromedical team prides itself on making custom, ultra-precise, US-made micromedical parts and products that change lives. It is the driving force behind the industry-leading design, development, prototyping and finishing of our clients’ products, all supported by our friendly and excellent customer service.

If the world needs it, we can manufacture it

AMS Micromedical’s 29,000 square foot advanced manufacturing facility is ISO-certified and FDA-approved and has all the equipment needed to create advanced micro-devices and components for any medical application. If the world needs it, we can make it better and smarter with the highest quality and precision.

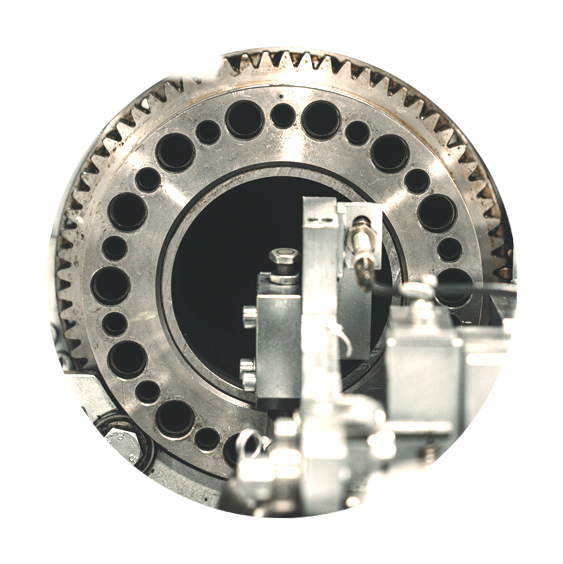

Machining

We create high-precision medical device components ranging in size from .1 mm to 20 mm using a variety of micromachining tools including CNC machines and Swiss turning machines. Materials commonly used include stainless steel and titanium.

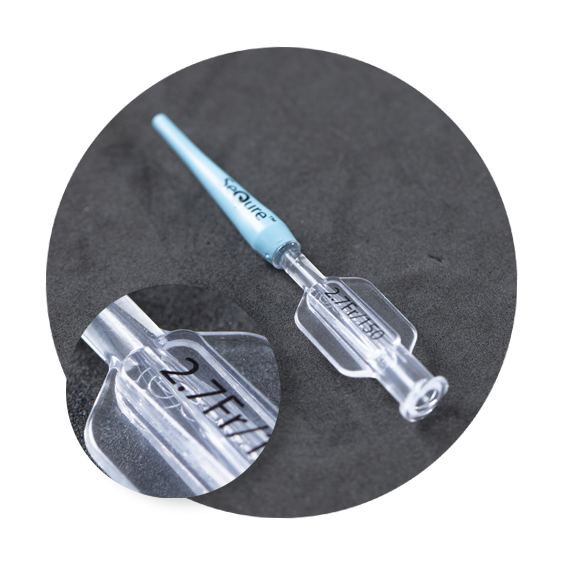

Plastic molding

Through plastic injection molding, we create custom engineered plastic components in quantities of any size. We also offer assembly of plastic components.

Finishing

Thanks to advanced finishing technologies including a state-of-the art laser engraver, every medical device component possesses the final touches and precise features our customers desire and require.

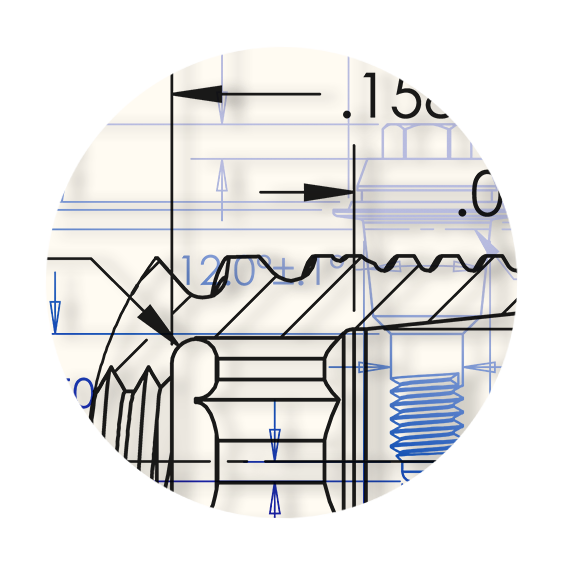

Engineering

Our development engineers help shape ideas into fully realized micro machine products through concepts, specs, designs and prototypes.

For selecting a contract manufacturer, we evaluate three requirements: quality of product, delivery time, and price. We have found AMS Micromedical to meet and exceed our expectations in each area.